- Personal Protection Face Mask PPE Gloves COVID 19 Test Kits Goggles Other

- Surgical Surgery Basic Surgical Instruments Microsurgical Instruments Neurosurgical Instruments Beauty

- Infusion Care Disposable Syringes Split bag Infusion Sets Disposable Blood Transfusion Catheters Medical Tapes and Adhesives Medical Disinfection

- Dental Consumables Cleaning Tools Auxiliary Tools Measuring Tools Orthodontic Materials Whitening Materials

- Orthopedic Consumables Prosthesis Series Fusion Device Series Bone Fixation Series

- Ophthalmology Consumables Auxiliary Class for Ophthalmology Cleaning Class for Ophthalmology Simple Instruments for Ophthalmology Measuring Instruments for Ophthalmology

- Home Health Care Medical Rehabilitation Health Massage Inspection

- Hospital Hardware Equipment Basic Equipment Refrigeration Equipment Pharmaceutical Machinery Equipment Medical Video Photography Equipment

- Medical Equipment and Production Equipment Physical Diagnostic and Treatment Equipment Imaging Instruments Analytical Instruments Disinfection Equipment Pet Medical

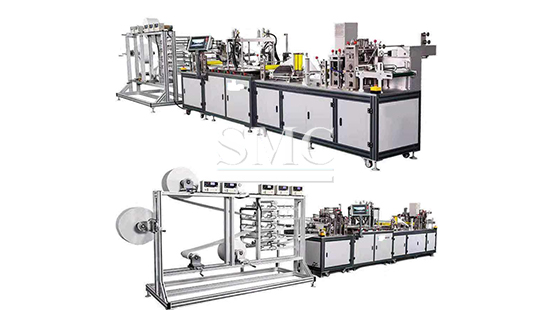

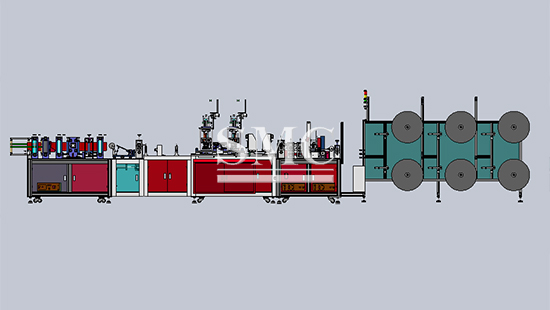

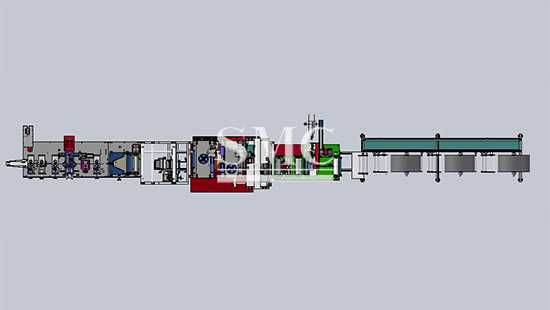

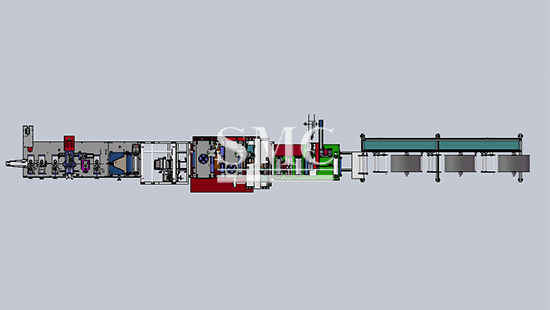

Fully Automatic Foldable Respirator Face Production Line

The working process of N95 Mask Machines are as follows: the multi-layer non-woven fabric rolls are subjected to compound roll welding after feeding. Nasal lines are welded after unwinding and cutting. Two rolls of earbands are welded after automatically unwinding and cutting to fixed length. Then masks are folded in half. After ultrasonic welding and fusion, the masks are rolling-cut and formed.

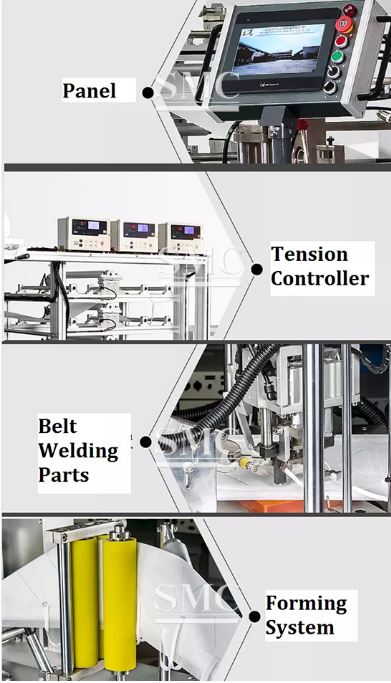

This machine has aluminum alloy rack. The appearance is light and beautiful. It can finish making the figuration at one time with the precision moulds. With imported high power ultrasonic it can weld firmly and waste materials will be outputted automatically. The computer program control and photoelectric detection make it have a high reliability and low failure rate.

Package of Fully Automatic Foldable Respirator Face Production Line:

here

for

price